Fitting Files: Golfweek Proves Fitting = Improvement

Posted by

Posted on

Fitting Files: Golfweek Proves Fitting = Improvement

This article was originally published by Golfweek on March 30, 2020.

The Fitting Files, a new Golfweek series, aims for the same kind of makeover. In the following pages and in future issues, we will share the basics of custom fitting and how golfers just like you were able to improve with professionally fit golf equipment that matches their swings and bodies.

To help, we enlisted Club Champion, one of the leaders in custom fitting with 74 locations throughout the United States. The company’s fitters have a brand-agnostic philosophy with a focus on matching players to their best gear, regardless of the name on the club. Using their universal hosel mechanism, Club Champion fitters can attach any head to any shaft, so golfers can test countless combinations of gear using TrackMan launch monitors and SAM PuttLab systems.

The three golfers featured this month all came to a Club Champion store near Chicago on a snowy January day in the hopes of getting an early jump on the season. The models of clubs they used before the fitting aren’t listed here, because it isn’t inherently important – their swings are theirs alone, and the results of their fittings almost certainly would be different for another player.

They all left with a reason to look forward to spring.

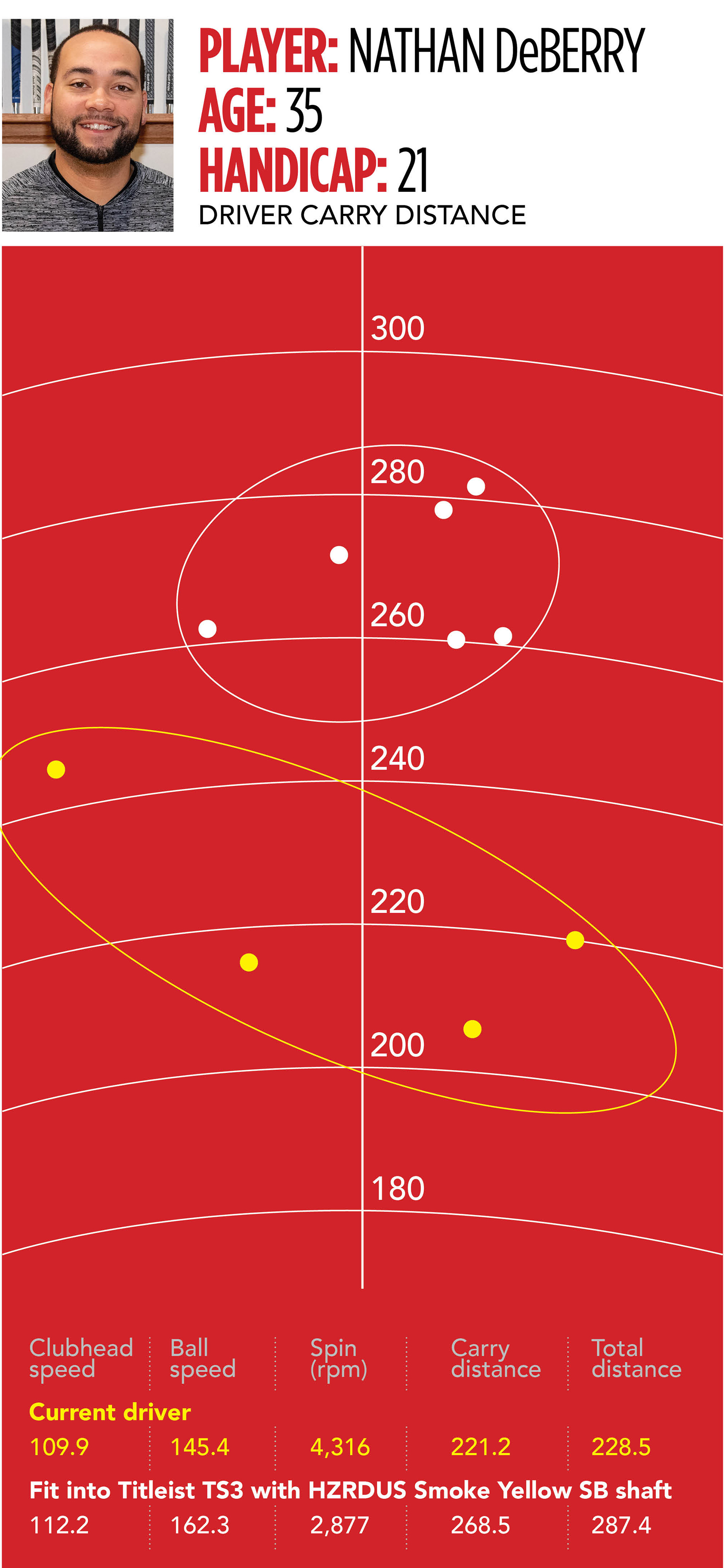

Player: Nathan DeBerry

Age: 35

Handicap: 21

Before: An athletic player with loads of power, DeBerry’s driver clubhead speed was almost 110 mph. That is nearly PGA Tour level, but after getting warmed up, he only averaged 221 yards of carry distance with his old 10.5-degree driver. DeBerry’s launch angle was 19.4 degrees, and he generated more than 4,300 rpm of spin off the tee. His moon balls were robbing him of yards, and his average driver distance was actually 3 yards shorter than with his 3-wood.

The Fitting: Smash factor describes the ratio of clubhead speed to ball speed and is a measure of efficiency that is capped by the USGA and R&A at 1.52. That means that if a player swings a club at 100 mph, the ball speed is not allowed to exceed 152 mph. Club Champion’s goal is for clients to achieve a smash factor of 1.48 or higher with their driver, and DeBerry’s was 1.32 with a tendency to slice.

“That number means you are leaving some serious yards out there,” said Brad Syslo, one of Club Champion’s most experienced fitters. “Every mile an hour of ball speed can be 3 to 5 yards.”

Syslo started by testing DeBerry with shafts of various weights. DeBerry had used a 60-gram shaft that came standard with his driver. After trying several models, he and Syslo discovered the Project X HZRDUS Smoke Yellow shaft reduced his excessive spin, lowered his ball flight and increased stability so his shots flew straighter.

Next, DeBerry tried driver heads on the Project X shaft. He liked several of them, and the Titleist TS3 with 8.5 degrees of loft provided him with the best match for his needs.

They repeated the process for DeBerry’s 3-wood and learned the same shaft, in a slightly heavier weight, fitted to a 15-degree TaylorMade SIM fairway wood produced more distance and a tighter dispersion pattern than his previous fairway wood.

Final impressions: “The shaft made a huge difference,” DeBerry said.

DeBerry gained 17 mph in ball speed with his driver, lowered his spin rate by about 1,500 rpm and reduced his launch angle by more than 7 degrees. His driver carry distance went up an astonishing 47 yards, his slice turned into a gentle fade and his smash factor climbed to 1.45. His new 3-wood also carried almost 13 yards farther than his previous fairway wood.

Player: Steven Jacobi

Age: 44

Handicap: 18

Before: Jacobi had never been custom fit for clubs and purchased a used driver online three years ago. A league golfer who plays twice a week in season, Jacobi loved his driver but arrived at his fitting searching for more distance and to reduce his slice.

The Fitting: Club fitter Andrew Moores explained that Jacobi was doing a lot of things well. His clubhead speed and spin rate were good, and his launch angle was not too bad. However, the shaft in Jacobi’s old driver was a bad match because of one key characteristic.

“When a shaft is too heavy and too stiff, you can’t get the head through, and the clubface stays open,” Moores said.

Moores and Jacobi tried six shafts at lower weights and learned an Accra FX 2.0 140 M3 shaft, which weighs about 45 grams, was ideal when set into a driver at a slightly flatter lie angle.

After finding the ideal shaft, Moores said, “You can see that his face-to-path measurement is almost 0, which means it’s square.”

Next, they started exploring heads. Jacobi liked Ping drivers, and a 9-degree G410 Plus with its adjustable hosel set to +1 proved to be the best fit.

Final impressions: The combination of the Accra FX 2.0 shaft and the Ping G410 driver helped Jacobi increase his ball speed by more than 4 mph, which resulted in 9 more yards of carry distance and 14 more yards overall. His dispersion pattern also tightened, and his drives flew straighter.

“Honestly, after tinkering and going through the fitting, that driver feels right,” Jacobi said.

“I think his distance is going to go up when he’s fresh,” Moores said after the fitting concluded with a slightly tired Jacobi. “When we started with this shaft, he was swinging 2 or 3 mph faster, so with his improved smash factor, that could be another 5 or 6 mph of ball speed.”

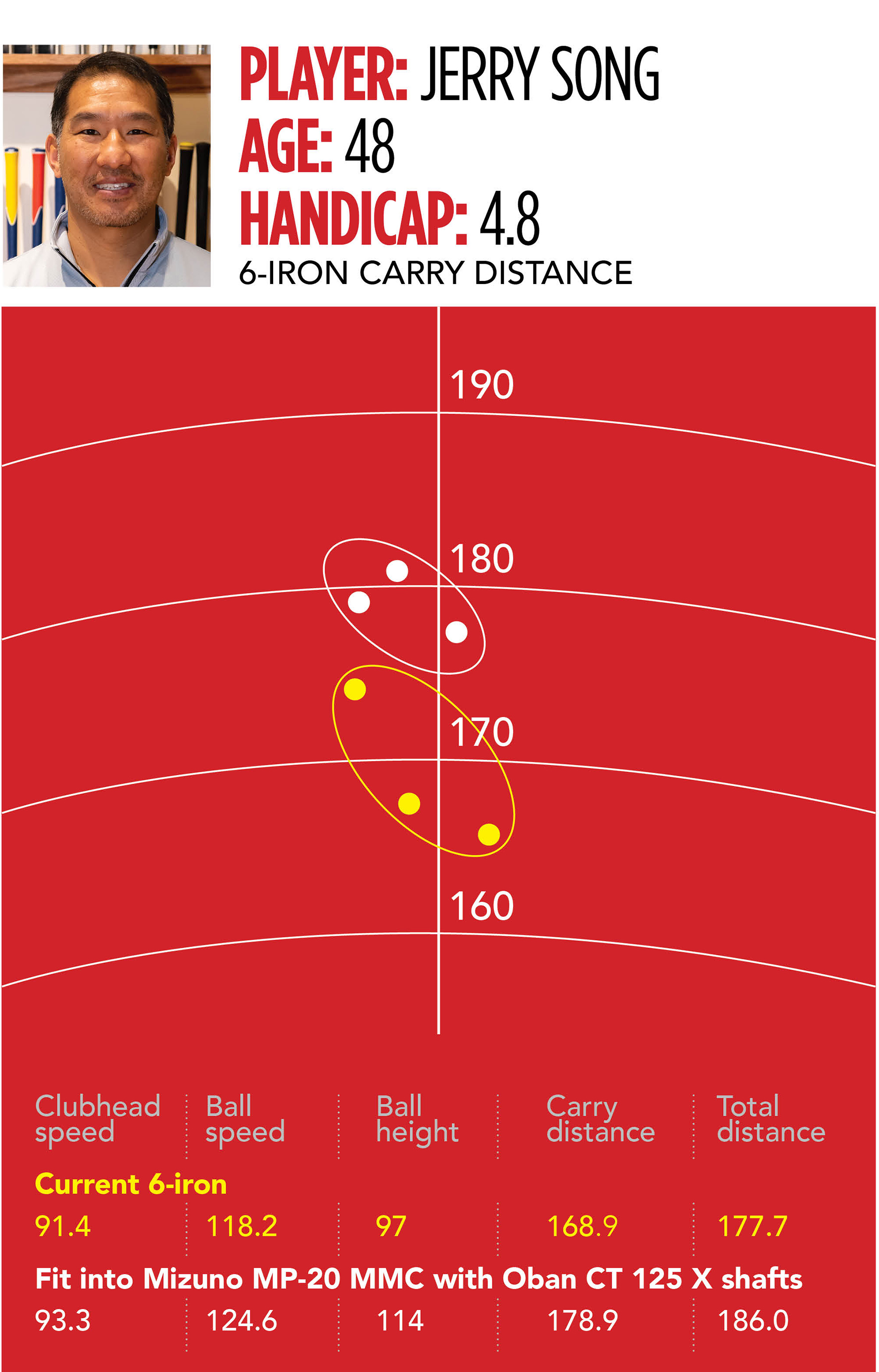

Player: Jerry Song

Age: 48

Handicap: 4.8

Before: Song is a steady golfer who plays two or three days a week. He loves the look and feel of classic muscleback blades, and like many accomplished players, Song is slow to make changes to his gear. He bought his irons seven years ago off the rack, but then about four years ago Song went to a Club Champion store for a whole-bag fitting. He likes a heavy iron, so the fitter added lead tape to the back of the heads.

“I hit a really high ball, so I’m looking to see if technology can help me hit it a little bit lower,” Song said before his fitting with Darrell Wyatt.

The Fitting: Trackman data revealed that Song’s typical 6-iron was flying a respectable 169 yards in the air with an apex height of 97 feet. Song believed he was hitting the ball too high, but Wyatt explained that his trajectory was close to ideal.

“His ball flight and height were not really too high for his standards. It felt high to him, but we were in a pretty good spot,” Wyatt said.

After testing various shafts, Song and Wyatt discovered that Oban CT 125 X steel shafts kept Song’s ball flight in the ideal height range while enhancing feel and delivering more ball speed.

“It just felt better in my hands, and I did not feel like it was dragging coming through,” Song said. He also said the shaft encouraged him to swing more smoothly and easily.

Wyatt saw that the stiffer shaft made contact more solid, and that helped Song’s efficiency.

After settling on the shaft, Song and Wyatt tested iron heads. He loved the look of Mizuno’s irons and discovered that the MP-20 MMC irons were a great fit on the Oban shafts. His ball speed increased 6 mph, his dispersion stayed tight and the ball came down more steeply, so approach shots would stop faster on the greens.

Final impressions: Song went from a muscleback blade to an iron that is forged from carbon steel with a copper underlayer, tungsten in the sole and titanium in the back of the heads. He loved the looks and those hidden technologies, but even good players can have misconceptions about their shots, and Song learned a few things.

“I’m a big weight guy and like my irons to be a little heavier, but understanding that I can go to an extra-stiff shaft, even though I’m getting older, was interesting,” he said. “But when I swung that shaft, it was easy. I didn’t have to muscle it. Everything went through crisp and I gained 9 yards!”

- Categories: Blog